Conventional Style Tracks | Interchangeable Style Tracks

Non Metal Core (NMC) Tracks | Anti-Vibration (AV) Tracks

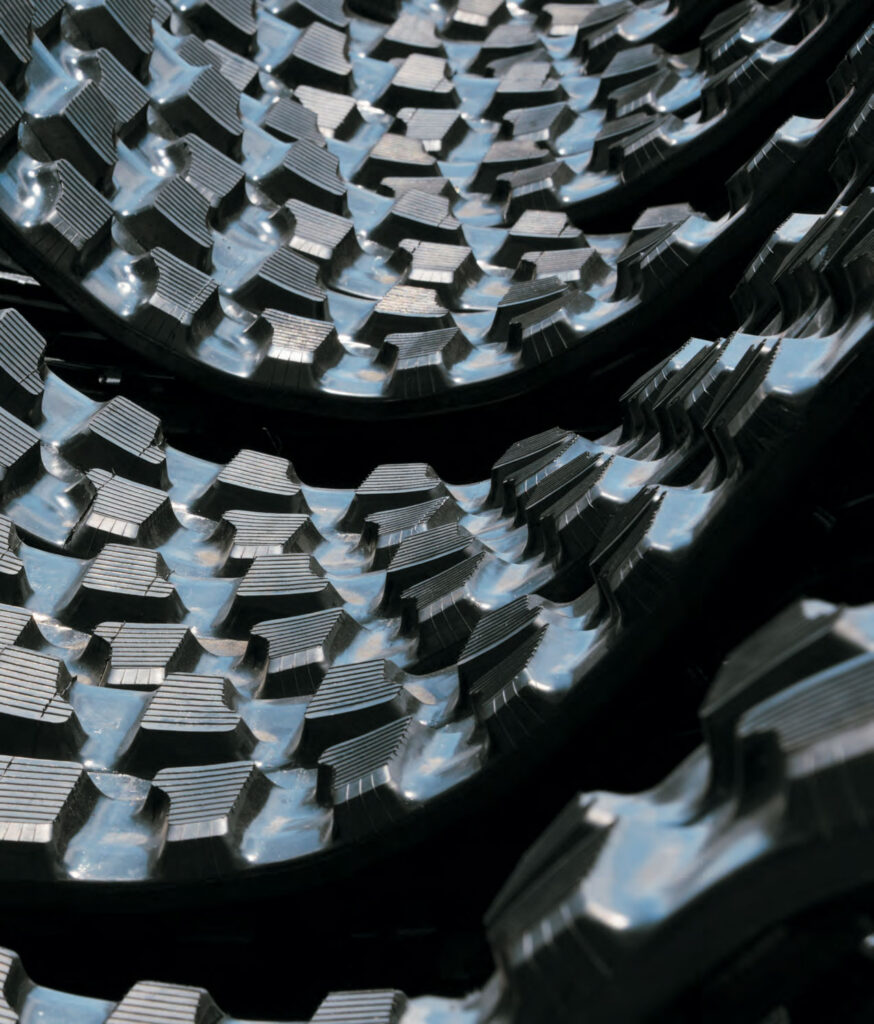

ITR RUBBER TRACKS are designed, engineered and manufactured using state-of-the-art technology, high quality materials and craftsmanship providing excellent quality and durability. ITR rubber tracks are produced to the highest standards based on years of field experience and the results of numerous operational tests in a wide range of working conditions.

ITR also manufactures a wide range of track frame components used on compact excavators, loaders and utility equipment including, track tensioners, sprockets, idlers, rollers and hardware.

ITR Rubber Track Structure and Main Features

ITR RUBBER TRACKS use “continuous cable” technology. This market-proven technology provides durability, with flexibility and strength throughout the complete track structure, minimizing premature wear during use.

ITR RUBBER TRACKS design integrates various layers of protection into the track providing protection to the cables and to the metal core inserts. A thick outer tread layer of rubber functions as additional protection to the track structure by absorbing surface wear, impact and abrasion.

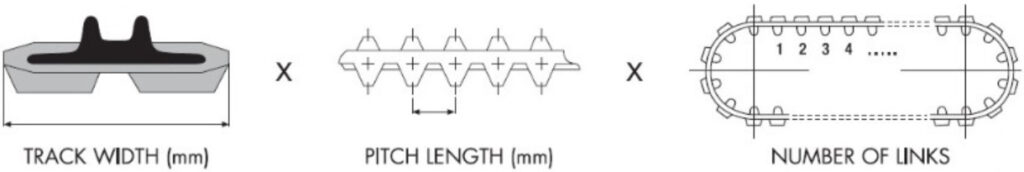

TRACK SIZE IDENTIFICATION

The ITR rubber track identification is carried out through 3 basic dimensions:

The width of the track, the length of the pitch of the internal metal guide and the number of metal links (guiding teeth) of the track.